I’m pleased and excited to announce the installation of Fenestra Molendini, my recent stained glass window project, at The Mill in Westport, NY.

The Mill is an 11,000 square foot former grain mill that was originally constructed in 1952 as the Champlain Valley Seed Cooperative. In 2021 the building was purchased by Catherine Ross Haskins and Taylor Haskins with the intent of restoring it into an extraordinary new home for innovative cultural experiences. The building houses a curated art exhibition program of world class contemporary art, a speakeasy (The Knock) and a performance space. Read more about The Mill here.

Fenestra Molendini is a site-specific stained glass window, created for The Mill’s Listening Room. In conceptualizing the design, I was inspired by the history of the building and the cathedral-like space that was once used for sifting and sorting grain. In eras gone by, The Mill’s sifting room did not have the large window openings that it has today. I thought about the flour mill workers of yore, and imagined them working within the space, without views of the outdoors and without natural light. Perhaps they occasionally paused their work and imagined the natural environment beyond the confines of the building.

Fenestra Molendini is Latin for ‘window of the mill’ or ‘mill window.’ Flour production has a long history, dating back to the beginnings of agriculture around 10,000 years ago, and is among the most significant of human developments. Fenestra Molendini is intended to honor the building’s transformation into its new iteration as a space filled with music, art, and social interaction and engagement as well as its history and former function as a site for the production of flour. In both scenarios, human effort is coordinated to sustain and nurture body and soul. The multi-layered abstraction loosely references an imaginary landscape, with the suggestion of cloud forms, blue skies, and allusions to wheat stalks and the flour sifting process. The imagery also subtly refers to 19th century American landscape painting, the digital language of early 1980s video games, and 19th century Japanese woodblock printing.

Fabricated by Franz Mayer of Munich

Below: a timeline of Fenestra Molendini’s fabrication and installation process.

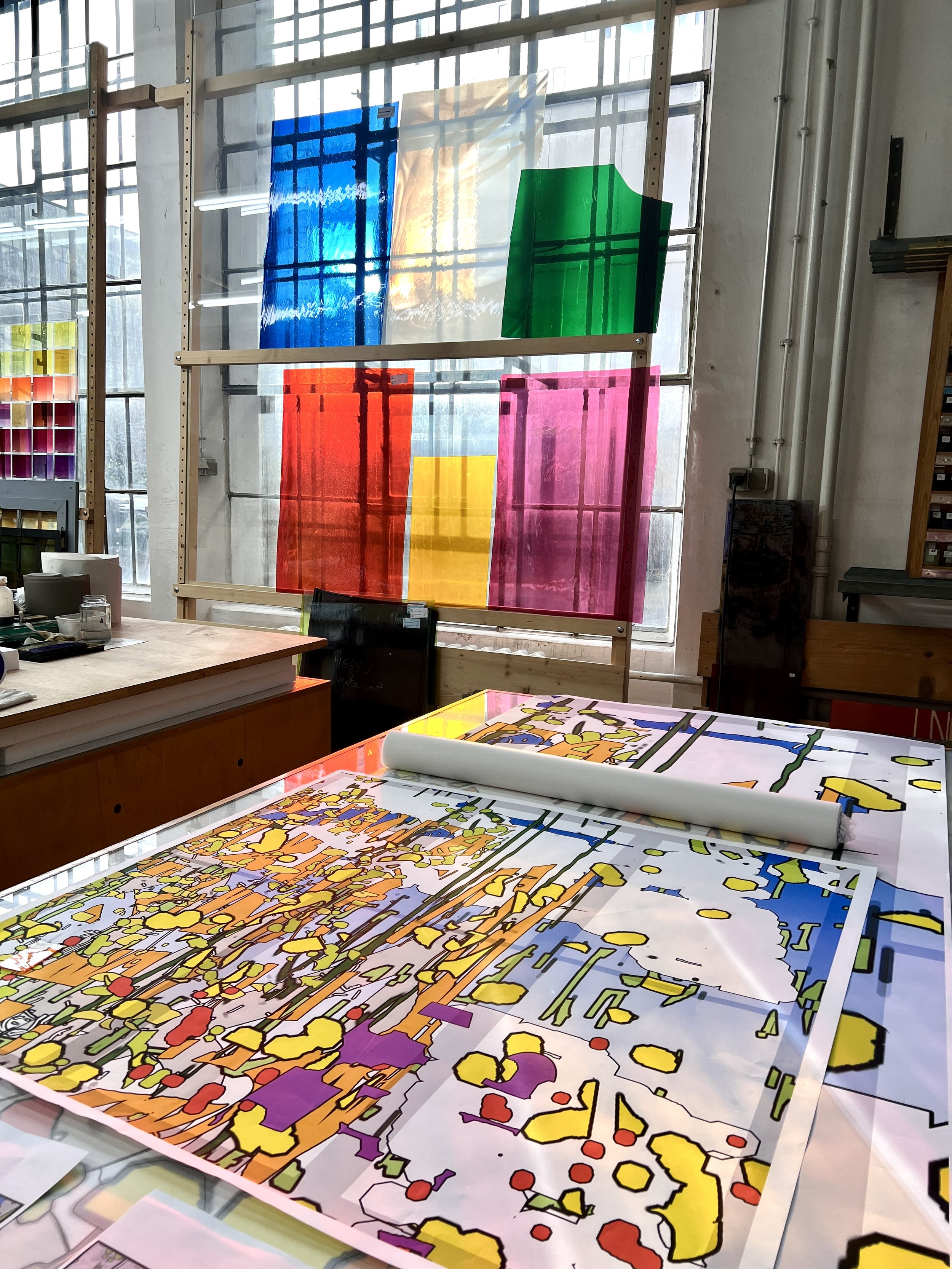

Viewing the window design printouts in Franz Mayer of Munich’s studio in Munich, Germany. The ceiling mirror allows the artisans to see the design at a greater distance.

While working on the design, I began with the idea of outlining each shape in black. Because stained glass requires lead lines—literally, strips of metal—to hold the glass pieces together, I decided that all shapes in the design would have a black outline, which would give the illusion of all shapes being leaded, creating a degree of visual complexity that would not actually be possible with leading. The window is made of six rectangular panels held in a metal frame. Each panel has multiple leaded sections which are pieced together.

Michael Mayer hoisting a printout of the design in Mayer of Munich’s viewing room. Seeing the design at the approximate height of its eventual installation helped us to determine if changes were necessary for legibility. I ended up simplifying a few things and removing visual clutter, while retaining the complexity that I desired.

Selecting colored glass for the palette of the window. The slabs of glass are mouth-blown into tubes which are cut and flattened into sheets. Within a given color, there are variations and irregularities (bubbles, color shifts, etc.) so we carefully selected the palette and set aside those specific sheets of glass for the fabrication process.

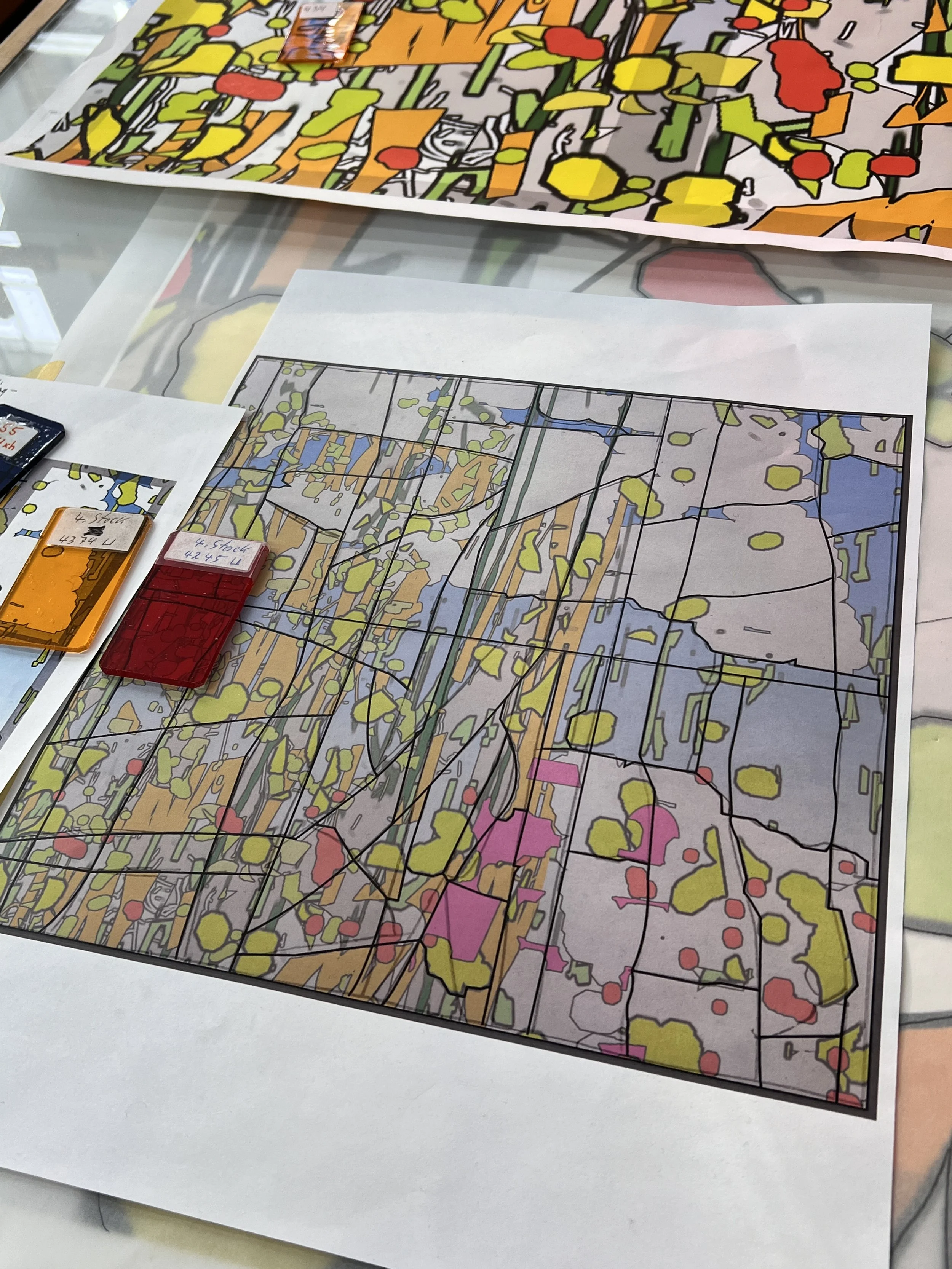

One of the most challenging aspects of this project was deciding on the location of the lead lines. The leading is structural, and also esthetic, and it should enhance shapes without truncating them in an unpleasant way. I drew many versions of the lead line pattern, using tracing paper over a printed sketch and also working on my sketch in Illustrator. Basically, the lead lines follow a loose grid. We had decided that specific colors would be leaded throughout the piece, which I had to take into consideration as I created the grid. Any shape that is held by lead needs to connect to the overall structure.

Final color palette

By the end of my week in Munich, we had a rough idea of the lead line pattern, and had determined a process for fabrication. This is the final color palette for the window. The big slabs of solid color are mouth-blown glass, and the samples at the top of the photo were created by painting and hand painting colors with glass pigments. The glass is then fired, and the colors permanently fuse to the glass.

Right: my design, printed at scale.

Left: glass sample. Here you can see the incredible fidelity to my concept. In this section, the orange-yellow glass (which is not solid color all the way through, but color sandwiched over clear glass) has been etched away in areas, then filled in with printed and hand-painted glass pigment, then fired. The result is perfect, giving the illusion of leaded lines.

The leading comes in different widths, and the color is created by applying a chemical patina. Here, we are checking the scale and appearance of the leading.

After my visit to FMoM, the artisans began the long task of creating the window. They built a wooden tray for each section, and began to carefully cut and piece the colors.

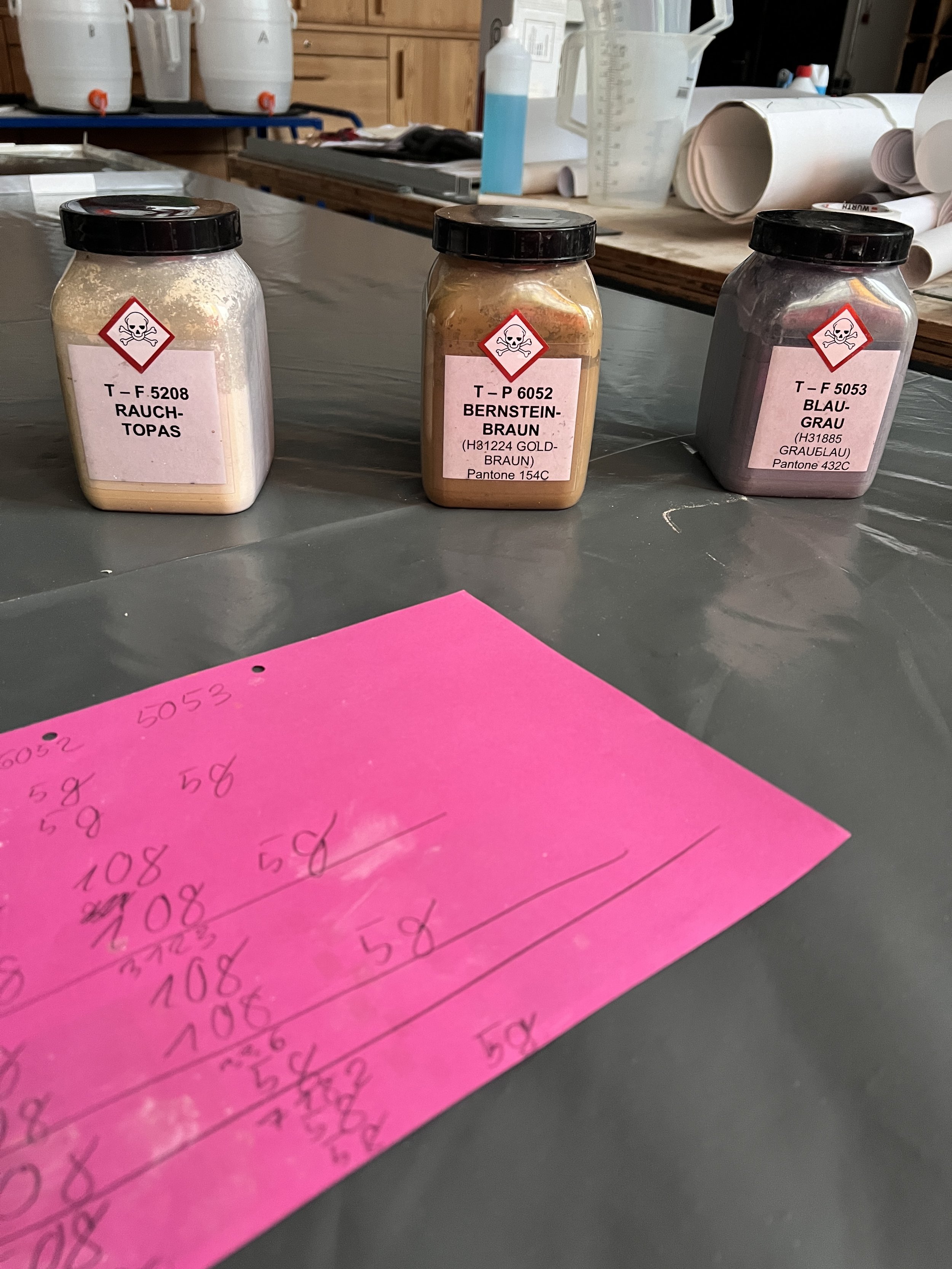

Tools of the trade

Glass pigments and color recipes. Similar to ceramic glazes, pre-fired glass pigments do not appear to be the color that they will be after firing.

Carefully dusting and wiping down one of the panels after the window arrived in Westport, NY.

After many months, the window was shipped to Westport, NY. In April 2025, I visited The Mill for the window installation. It was a delicate operation! Each panel had to be carefully unpacked, checked over, and cleaned and dusted before being taken up the lift and installed in the custom window frame.

Art installation takes a village!

It was thrilling to see the window throwing colored light onto the floor! Of course, the intensity and direction of the light path changes throughout the year.

No one will see the window in such close proximity, but it was really enjoyable to see all of the subtleties in the mouth-blown glass. It is the most gorgeous medium. In some ways, I have always thought that computer monitor color is the only comparable color because it, too, is back-lit. The transparency and light create a sense of incredibly saturated, bright, luminous color.

Fenestra Molendini, 2025.